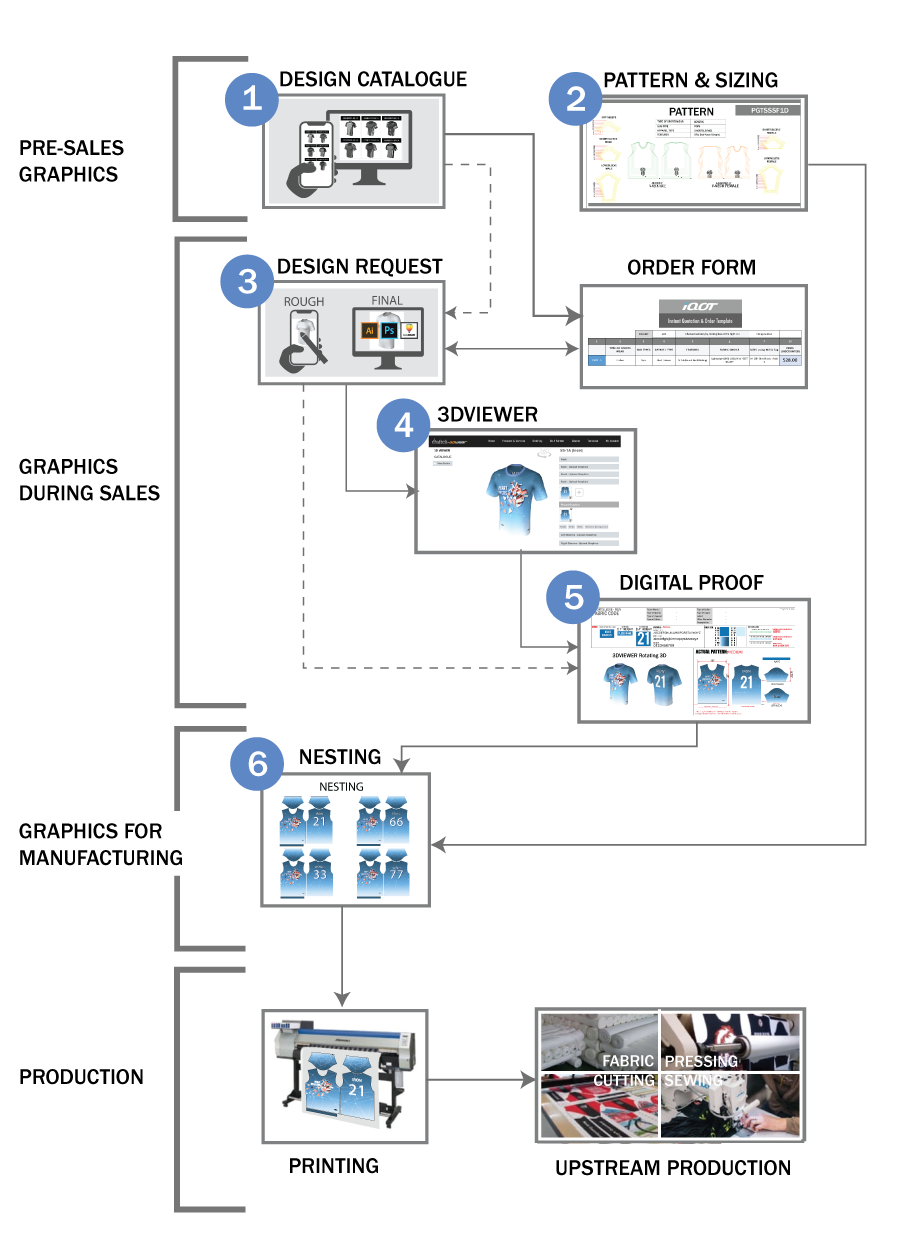

OUR MANUFACTURING PRINCIPLES AND PROCESSES

Crafteli is following two principles in manufacturing:

Why Italian-inspired?

Manufacturing is an art in Italy. That is why all employees, including the owner, view themselves as artists. This is the artisan concept that guides Crafteli in its day-to-day operation as a manufacturer of custom sublimated sportswear. As artisans, Crafteli employees try to visualize perfection even before the first stitch is sewn.

Why ethical manufacturing?

The sad thing about the garment industry is that there are still companies who operate as sweatshops. This practice may be cost-effective but the downside is that it does not provide good working conditions and may result to poor quality, as the main focus is on quantity. Sweatshops may be considered unethical manufacturers.

Crafteli Company strongly supports the Fashion Revolution and upholds ethical manufacturing. Crafteli put up his own factory and now employs regular workers who are paid with basic salaries, overtime fees, holiday pays, and enjoy medical benefits. Crafteli sewers also work inside air-conditioned rooms for comfort.

Now, Crafteli has proven that following a more ethical manufacturing set-up makes good business sense as it resulted to better quality and higher productivity.

- Italian-inspired manufacturing concept

- Ethical manufacturing set-up

Why Italian-inspired?

Manufacturing is an art in Italy. That is why all employees, including the owner, view themselves as artists. This is the artisan concept that guides Crafteli in its day-to-day operation as a manufacturer of custom sublimated sportswear. As artisans, Crafteli employees try to visualize perfection even before the first stitch is sewn.

Why ethical manufacturing?

The sad thing about the garment industry is that there are still companies who operate as sweatshops. This practice may be cost-effective but the downside is that it does not provide good working conditions and may result to poor quality, as the main focus is on quantity. Sweatshops may be considered unethical manufacturers.

Crafteli Company strongly supports the Fashion Revolution and upholds ethical manufacturing. Crafteli put up his own factory and now employs regular workers who are paid with basic salaries, overtime fees, holiday pays, and enjoy medical benefits. Crafteli sewers also work inside air-conditioned rooms for comfort.

Now, Crafteli has proven that following a more ethical manufacturing set-up makes good business sense as it resulted to better quality and higher productivity.